-

- Home

- About Us

- Products

- Cold Cutting Equipment And Accessories

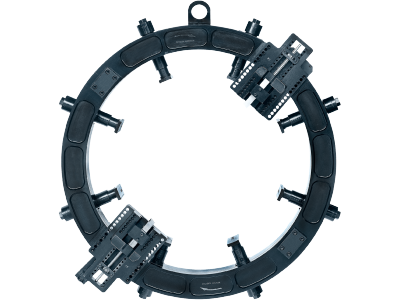

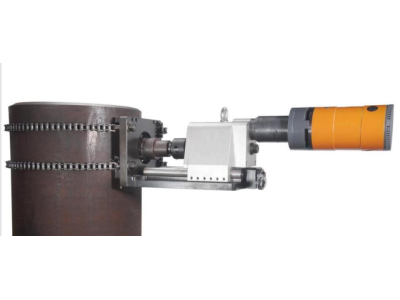

- Split Frame Pipe Cutting And Beveling Machine

- Pipe Beveling And Facing Machine

- Pipe Facing Machine

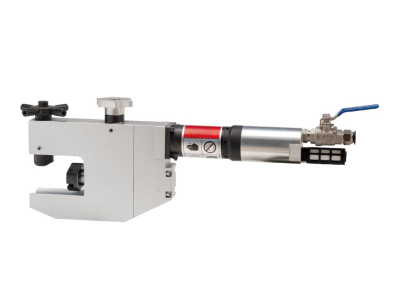

- Stationary Pipe Cutting And Beveling Machine

- Stationary Pipe Beveling Machine

- Elbow Beveling Machine

- Orbial Pipe Cutting Machine

- Flange Facing Machine

- Pipe Hole Cutter

- Pipe Threading Machine

- Plate Beveling Machine

- Portable Planar Milling Machine

- Portable Linear Boring Machine

- Shaft Diameter Repair Machine

- Cutting Tools And Accessories

- Thermal Cutting Equipment And Accessories

- Plasma Cutting Equipment And Accessories

- Welding Equipment And Accessories

- Flow Control Equipment And Accessories

- Bolt Tightening Equipment And Accessories

- Cutting And Welding Auxiliary Equipment

- Grinding Equipment And Accessories

- Others

- Cold Cutting Equipment And Accessories

- News

- Resources

- Contact Us

-

-