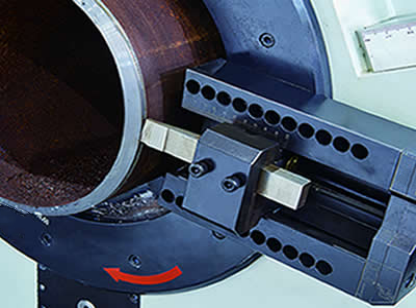

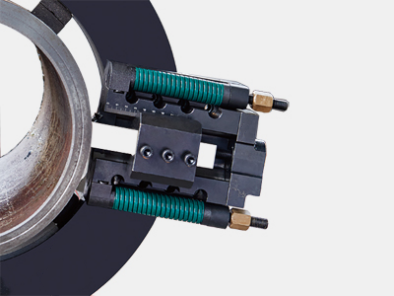

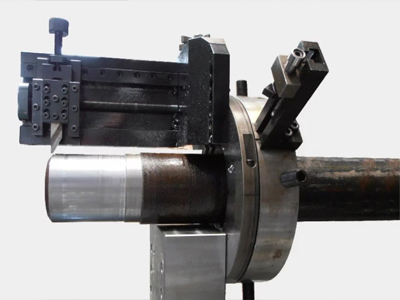

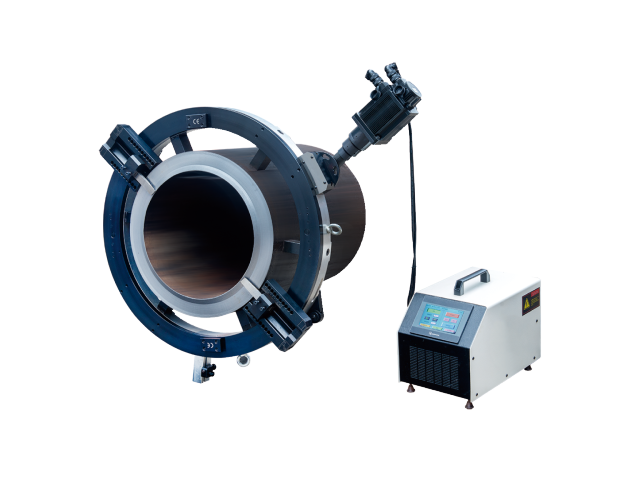

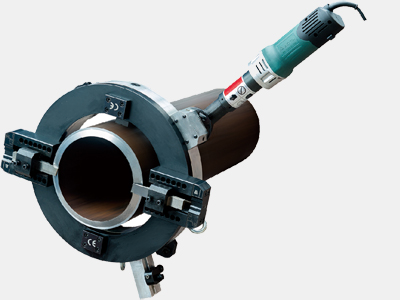

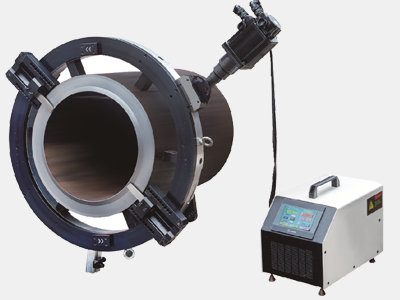

Standard split frame pipe cutting and beveling machine, designed to cut, bevel, single point, counter-bore and face on the pipe, tube and flanges. It is a portable pipe cutting and beveling machine tools of clamshell style. smartly designed, ability to split in half at the frame, easy to install on the pipe line. It is comprehensive used in pipework of oil, gas, food, petroleum, chemical, boiler, medicine machine, nuclear power, and power supply construction. 16 models are available in 6inch (152.4mm) increments, with additional sizes available by special order.

-

- Home

- About Us

- Products

- Cold Cutting Equipment And Accessories

- Split Frame Pipe Cutting And Beveling Machine

- Pipe Beveling And Facing Machine

- Pipe Facing Machine

- Stationary Pipe Cutting And Beveling Machine

- Stationary Pipe Beveling Machine

- Elbow Beveling Machine

- Orbial Pipe Cutting Machine

- Flange Facing Machine

- Pipe Hole Cutter

- Pipe Threading Machine

- Plate Beveling Machine

- Portable Planar Milling Machine

- Portable Linear Boring Machine

- Shaft Diameter Repair Machine

- Cutting Tools And Accessories

- Thermal Cutting Equipment And Accessories

- Plasma Cutting Equipment And Accessories

- Welding Equipment And Accessories

- Flow Control Equipment And Accessories

- Bolt Tightening Equipment And Accessories

- Cutting And Welding Auxiliary Equipment

- Grinding Equipment And Accessories

- Others

- Cold Cutting Equipment And Accessories

- News

- Resources

- Contact Us

-

-

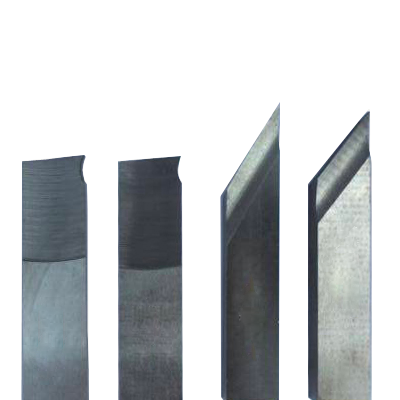

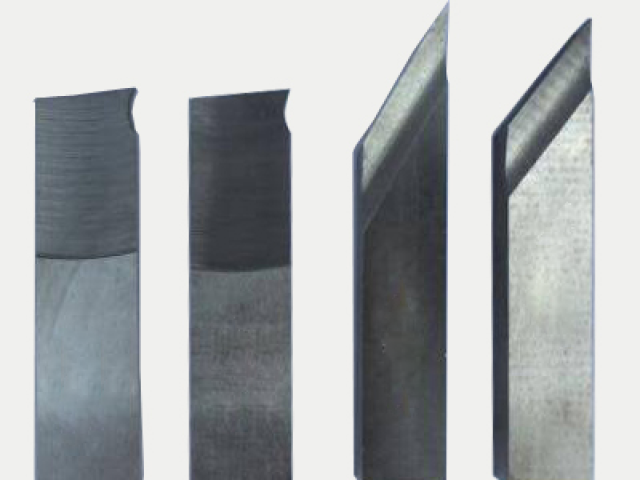

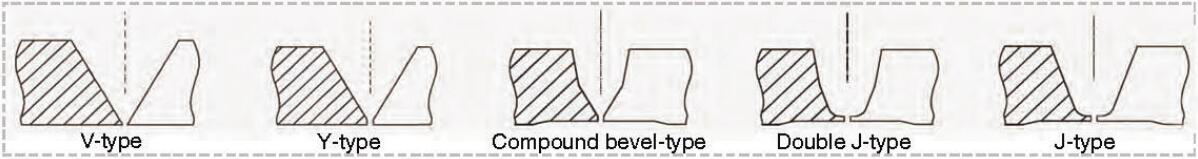

Other beveling shape, angle and pipe material, please declare before order

Other beveling shape, angle and pipe material, please declare before order