|

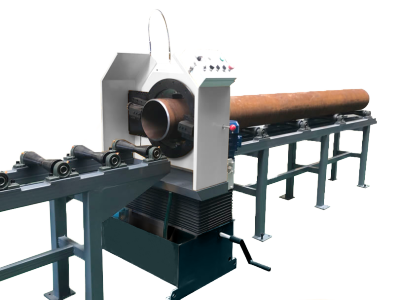

Model

Technical Parameter

|

CTA-6

|

CTA-12

|

CTA-16

|

CTA-24

|

CTA-32

|

CTA-40

|

|

Working Range(mm)

|

Φ34-168(DN25-150)

|

Φ48-325(DN40-300)

|

Φ60-426(DN50-400)

|

Φ325-630(DN300-600)

|

Φ508-830(DN500-800)

|

Φ711-1020(DN700-1000)

|

|

Clamping Jaw

|

Main/Auxiliary Dual Clamping

Four-Jaw Self-Centering

|

Main/Auxiliary Dual Clamping

Four-Jaw Self-Centering

|

Main/Auxiliary Dual Clamping

Four-Jaw Self-Centering

|

Main/Auxiliary Dual Clamping

Six-Jaw Self-Centering

|

Main/Auxiliary Dual Clamping

Six-Jaw Self-Centering

|

Main/Auxiliary Dual Clamping

Eight-Jaw Self-Centering

|

|

Power

|

13.0KW

|

16.0KW

|

16.0KW

|

20.0KW

|

27.0KW

|

27.0KW

|

|

Pipe Material

|

Carbon steel, alloy steel, stainless steel, duplex stainless steel, low-temperature steel, heat-resistant steel

|

|

Working Thickness

|

Stainless steel, alloy steel:3-20mm,Carbon steel:3-25mm

|

|

Beveling Type

|

I-type, V-type, J-type, Compound-type

|

|

Servo Feed

|

Mitsubishi Servo Motor + High-Precision Planetary Reducer + Linear Guide

|

|

Tool Holder

|

Standard: Cutting tool holder(1set), beveling tool holder(2sets)

Optional: Cutting tool holder(2sets), beveling tool holder(2sets)

|

|

Clamping Method

|

Electrically actuated multi-jaw self-centering concentric clamping ensures uniform circumferential force distribution on the pipe. This design prevents deformation during the processing of thin-walled steel pipes, while also providing a certain degree of rounding correction for thin-walled pipes with excessive ovality.

|

|

*Clamping Jaw Layers

|

Two layers, with one layer mounted on the main unit's telescopic clamping jaws (no disassembly required). For pipe diameter adjustments within the machine's processing range, only one layer needs to be disassembled/installed. A slide-out mechanism enables rapid tooling change, with replacement time ≤5 minutes.

|

|

*Minimum Processable Pipe Length

|

CTA-6, CTA-12, CTA-16, CTA-24: 250mm

CTA-32, CTA-40: 300mm

|

|

*Minimum Finished Pipe Length

|

50mm (though length is theoretically unrestricted in principle).

|

|

Base Lifting System

|

The beveling machine is equipped with an integrated electric lifting base, enabling vertical height adjustment of the machining head. The system comprises:

l Motor reducer

l Four sets of ball screw actuators

l Transmission mechanisms

|

|

Base Lifting Method

|

Synchronized lifting via four ball screw actuators based on the pipe diameter.

|

|

Base Lifting Stroke

|

CTA-6≥150mm,others≥250mm

|

|

Base Lifting Speed

|

≥400mm/min

|

|

Tool Advance/Retract Control

|

Servo motor precisely controls tool movements: Rapid Feed

, Working Feed, Idle Feed, Rapid Retract, Equipped with Position Memory Function

|

|

Load Feed Speed (Working Feed)

|

Carbon Steel: ≤10mm/min, Stainless Steel/Alloy Steel: ≤6mm/min

|

|

Feed Rate

|

0.05-0.5mm/r

|

|

*Idle Feed Speed (Rapid Advance/Retract)

|

≮300mm/min

|

|

Cooling Method

|

Cutting fluid circulation cooling

|

|

Processing Accuracy

|

Beveling Face Perpendicularity: ≤1mm, Surface Finish: ≤Ra6.3, Angular Deviation: ≤0.5°

|

|

Control System

|

Japanese Mitsubishi PLC CNC program for automatic control, with 10-inch human-machine interface (HMI) for input and display of processing parameters.

|

|

*Specialized Program for Stainless Steel & Alloy Steel Processing

|

Embedded with proprietary processing programs developed by our company for stainless steel and alloy steel. Utilizes "Stepping Feed" technology, integrating Retract Control during feeding to achieve Chip Breaking & Evacuation, preventing chip entanglement, tool jamming, or blade chipping. Tool Life Enhancement: Over 3 times longer than conventional cutting/beveling machines.

|

|

Process Storage & Recall

|

Allows storage of optimized processing parameters in the system. Enables direct recall of programs for identical pipes in subsequent operations. Supports Preset, Store, Recall of processing programs.

|

|

Intelligent Parameter Auto-Search & Matching

|

Automatically searches and matches suitable processing parameters from the database after selecting material type and inputting pipe diameter/wall thickness, minimizing setup errors and operational risks.

|

|

Height Adjustment for Pipe Diameter Variation

|

Automatically adjusts the tool head’s center height based on preset pipe diameter to ensure alignment with the pipe axis, accommodating height variations across different pipe sizes.

|

|

Operational Simplicity

|

User-friendly design with minimal learning curve. Requires only basic parameter input to initiate processing.

|

|

*Optional

|

□ Automatic Chip Conveyor & Collection Cart

□ Pipe Conveying Roller Bed

□ Raw Pipe Auto-Loading System

□ Finished Pipe Auto-Unloading System

□ Residual Pipe Auto-Unloading System

□ Pipe Storage Rack

□ CNC Pipe Length-Measuring & Conveying System

□ Short Pipe Auto-Ejecting Robotic Arm

□ Full-Bundle Pipe Lifting/Loading Machine

□ Pneumatic/Laser Online Marking System

□ Industrial PC & Nesting Software

□ MES System Communication Module (Data Acquisition & Transmission)

|

|

Drive

|

3-Phase 5-Wire 380V±10%, 50Hz

|