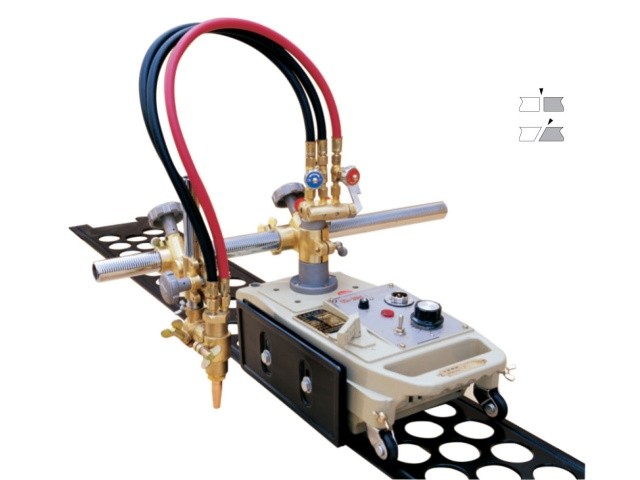

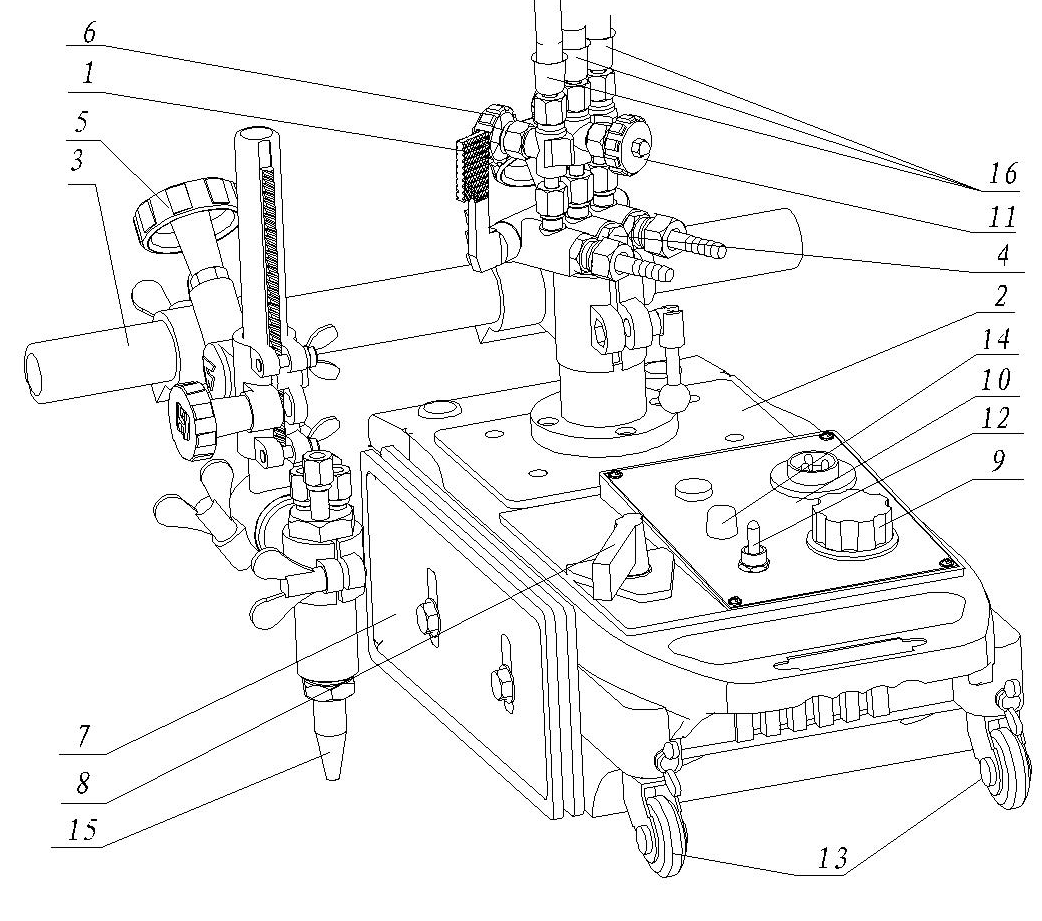

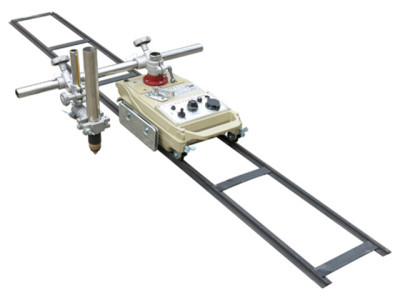

The "CG1-30H" portable automatic gas cutting machine is a new product developed and manufactured by Warwick. The internal structure of the machine is reasonably designed and the appearance is beautiful. Under the guidance of customers, a number of technical and process improvements have been made. Due to the use of new materials and strict requirements on parts processing technology, the operability, durability and heat insulation capacity of the machine have been greatly improved. For example, the moving parts, the upper and lower moving seats, the fire mouth clamp, etc. are all made of copper materials, so they are not easy to break or dent. The worm gear is made of bronze and is durable.

-

- Home

- About Us

- Products

- Cold Cutting Equipment And Accessories

- Split Frame Pipe Cutting And Beveling Machine

- Pipe Beveling And Facing Machine

- Pipe Facing Machine

- Stationary Pipe Cutting And Beveling Machine

- Stationary Pipe Beveling Machine

- Elbow Beveling Machine

- Orbial Pipe Cutting Machine

- Flange Facing Machine

- Pipe Hole Cutter

- Pipe Threading Machine

- Plate Beveling Machine

- Portable Planar Milling Machine

- Portable Linear Boring Machine

- Shaft Diameter Repair Machine

- Cutting Tools And Accessories

- Thermal Cutting Equipment And Accessories

- Plasma Cutting Equipment And Accessories

- Welding Equipment And Accessories

- Flow Control Equipment And Accessories

- Bolt Tightening Equipment And Accessories

- Cutting And Welding Auxiliary Equipment

- Grinding Equipment And Accessories

- Others

- Cold Cutting Equipment And Accessories

- News

- Resources

- Contact Us

-

-