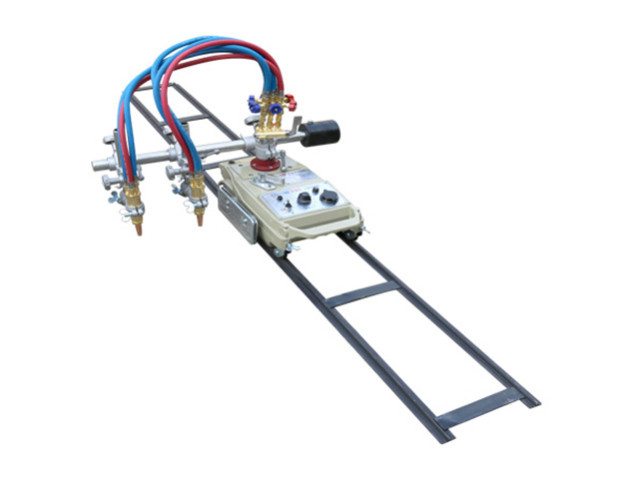

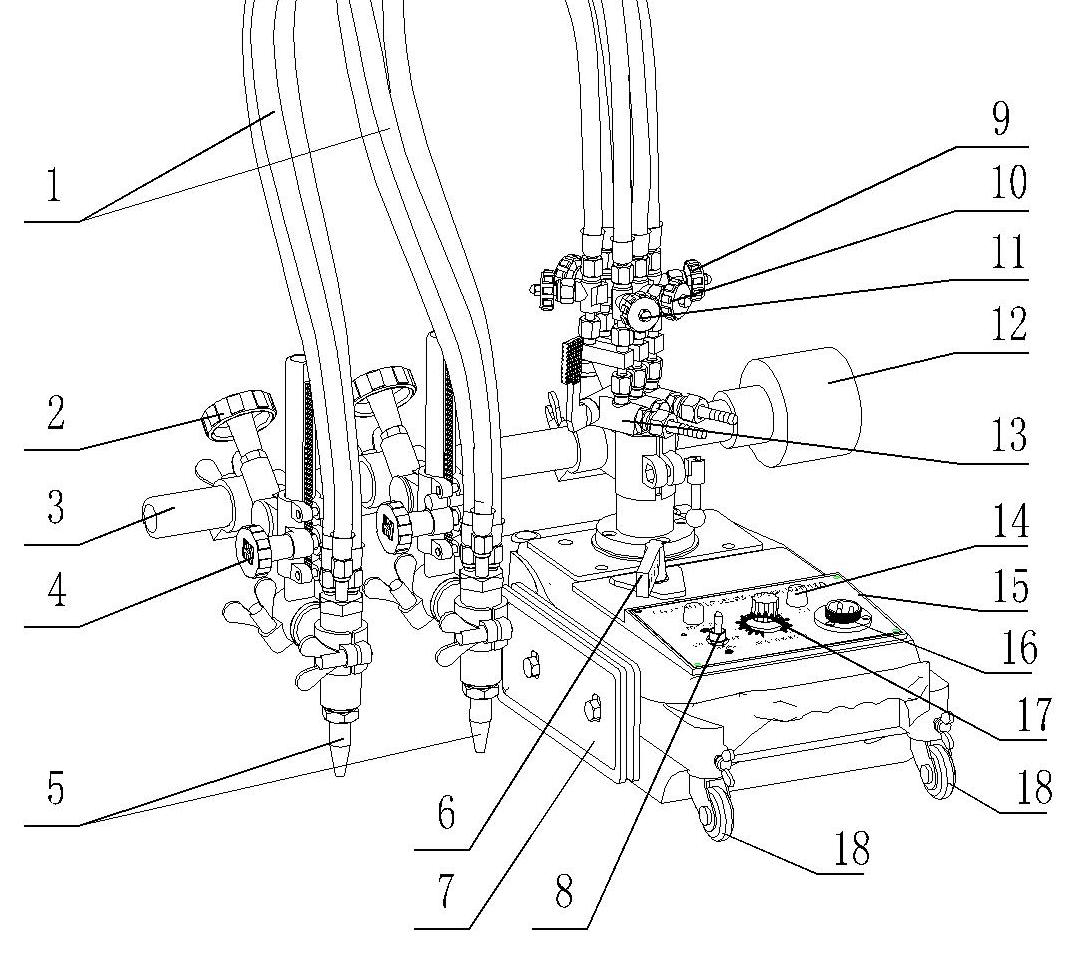

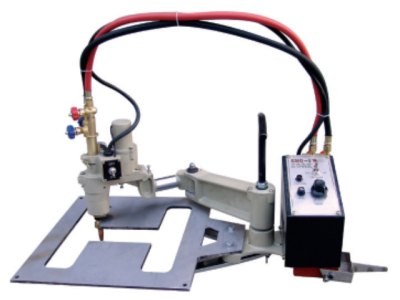

The "CG1-100" trolley-type double-torch gas cutting machine is one of the cutting series products of Warwick Company. The internal structure of the machine is reasonably designed; the appearance is beautiful and elegant. This product is based on the CG1-30 and has undergone technical discussions, and has undergone a number of technical innovations and process improvements. This machine uses new materials and strict requirements on parts processing technology, which greatly improves the machine's operability, durability, and heat insulation capabilities, and greatly enhances its practical range. As the name "double cutting torch" suggests, the machine can carry two cutting torches, which can cut materials at the same time, and can also be used together to cut V-shaped or X-shaped grooves.

-

- Home

- About Us

- Products

- Cold Cutting Equipment And Accessories

- Split Frame Pipe Cutting And Beveling Machine

- Pipe Beveling And Facing Machine

- Pipe Facing Machine

- Stationary Pipe Cutting And Beveling Machine

- Stationary Pipe Beveling Machine

- Elbow Beveling Machine

- Orbial Pipe Cutting Machine

- Flange Facing Machine

- Pipe Hole Cutter

- Pipe Threading Machine

- Plate Beveling Machine

- Portable Planar Milling Machine

- Portable Linear Boring Machine

- Shaft Diameter Repair Machine

- Cutting Tools And Accessories

- Thermal Cutting Equipment And Accessories

- Plasma Cutting Equipment And Accessories

- Welding Equipment And Accessories

- Flow Control Equipment And Accessories

- Bolt Tightening Equipment And Accessories

- Cutting And Welding Auxiliary Equipment

- Grinding Equipment And Accessories

- Others

- Cold Cutting Equipment And Accessories

- News

- Resources

- Contact Us

-

-